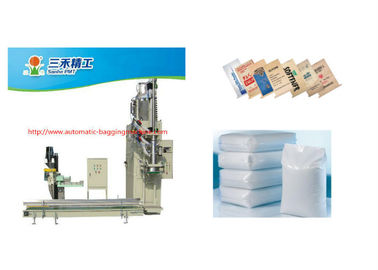

DCS-25FWG 25 Kg Weigh Packing Machine Bags Filling Packer Equipment

A. What is 25 kg electronic packing scale:

Electronic packing scale consists of weighing unit, sewing machine, conveying device, pneumatic system, dust removal system, quantitative packing control, etc. the whole weighing process is controlled by PLC and completed automatically.

B. Working principle of 25 kg electronic packaging scale:

When the electronic packaging scale enters the automatic operation state, the weighing control system opens the feeding door to start feeding, which is a fast and slow feeding mode; when the material weight reaches the fast feeding setting value, stop the fast feeding and keep the slow feeding; when the material weight reaches the final setting value, close the feeding door to complete the dynamic weighing process;

At this time, the system checks whether the bag clamping device In the predetermined state, when the packaging bag has been clamped, the system sends a control signal to open the unloading door of the weighing bucket, and the material enters the packaging bag.

The bag clamping device will be released, and the packaging bag will fall automatically; after the packaging bag falls, the sewing bag will be carried out and transported to the next station. It operates automatically in such a cycle.

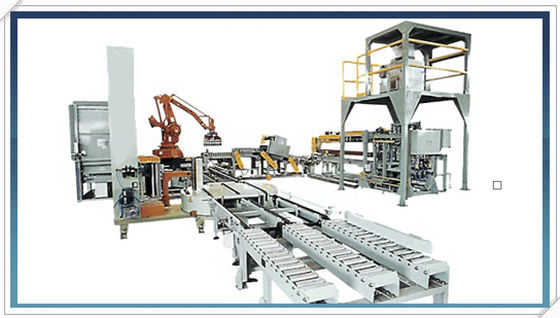

C. Generally, a packing & palletizing line includes: Electric Cabinet, sewing machine,Sewing conveyor, Bag push machine, Reshapen conveyor,Metal detector,Weight checker,Bag Rejecter,Ink-jet printer conveyer,Ink-jet printer ,Pallet magazine,Palletizing conveyor ,Robot, Wrapping Machine ,Finished palletizing conveyor.

D. According to the different styles of packaging bags, it can be divided into open mouth bag packing machine and valve type bag packing machine.

Series: Impeller Feeder

This series of machines are designed for super fine powders and granules with medium to high bulk density and small parcel size. The unique impeller design allows for a fast and uniform feed flow to maintain a fast packing speed. Applicable materials include: Cement, Dry Mortar, Kieselquhr, Perlite Additive, Lime Carbonate and Siliceous Dust etc.

Packaging weight: 25 kg

Power consumption: 5 - 7. 5 KW

Product characteristics :

1. Multi-stage frequency conversion design, high packaging accuracy.

2. They are durable and non-deformable, and have excellent stability.

3. It can be equipped with explosion-proof control system to meet the packaging requirements of conductive materials.

4. Dust-free operation, low noise, no spillover, reduce powder consumption.

5. Adopt imported electronic weighing system, machine automatic metering, automatic blanking, automatic shutdown.

6. After three independent quality inspections, there are more than 50 main inspection standards to strictly guarantee the quality of the products.

7. The technology is mature and the failure rate is low.

Our Services :

1. one year guarantee for whole machine except for wear parts;

2. 24 hours technical support by email;

3. calling service;

4. user manual available;

5. reminding for the service life of the wearing parts;

6. installation guide for clients from both China and abroad;

7. maintance and replacement service;

8. whole process trainling and guidance from our technicians.High quality of after-sales service symbolizes our brand and ability. We pursue not only good quality products, but also best after sales service. Your satisfaction is our final purpose.

FAQ :

1. Are you a trading company or a factory?

---We are factory sell directly, and welcome to visit our factory in Changshu city,Suzhou,Jiangsu Province China.

2. Can you guarantee the quality of your valve bag packing machine?

---We have passed CE&ISO9001, and our packing machines have been sent to Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, America, etc.

3. How many years have you been manufacturing this machine?

---Since the foudation of our company, we have been manufacturing the machine, which updated many times, now the machine runs stable and of high quality. we build on the year of 1998.

| |

DCS-25GO7N)

net weight type for granules

|

DCS-25(PO2G)

Gross weight type for granules

|

DCS-25(PO2N)

Net weight type for powder

|

DCS-25(PO4G)

Vertical screw type

|

|

Scope of application

|

|

Suitable materials

|

Granular material or powder material with fine flowability

|

powder material or Fine powder

|

powder material

|

Easy to bridging or raised dust of ultrafine powder

|

|

Suitable packing container

|

Open mouth bag, box, barrel

|

Open mouth bag, box, barrel

|

Open mouth bag, box, barrel

|

Open mouth bag, box, barrel

|

|

Feeding type

|

Gravity

|

horizontal screw

|

horizontal screw

|

Vertical screw

|

|

Alternative feeding type

|

Vibrator

|

Vibrator, belt

|

Vibrator, belt

|

× |

|

Technical parameters

|

|

Weighing range

|

1-100 |

10-50 |

10-50 |

1-50 |

|

Packing speed(bag/H)

|

300-800 |

100-200 |

100-500 |

100-180 |

|

Packing Accuracy

|

Generally (+/- )0.2% ( Note: special materials shall depend on the industrial standard )

|

|

Control function

|

|

Automatic tare

|

○ |

○ |

○ |

○ |

|

Automatic quick and slow feeding

|

○ |

○ |

○ |

○ |

|

Automatic free fall compensation

|

○ |

○ |

○ |

○ |

|

Automatic minus deviation

|

▲ |

▲ |

▲ |

▲ |

| Automatic over weight alarms |

○ |

○ |

○ |

○ |

| diagnosis failure |

○ |

○ |

○ |

○ |

|

Manual/Automatic mode conversation

|

○ |

○ |

○ |

○ |

|

Communication port

|

▲ |

▲ |

▲ |

▲ |

|

Regulatory function

|

| Manual adjusting the height of bag |

○ |

○ |

○ |

○ |

| Important auxiliary function |

| Arch break function of hopper |

× |

○ |

○ |

○ |

| Vibration at the bottom of the bag |

▲ |

▲ |

▲ |

▲ |

| Powder protection |

| Inflatable seal |

▲ |

▲ |

▲ |

▲ |

| Negative pressure dusting(not contain duster) |

▲ |

○ |

○ |

○ |

| Valve for leak-proof |

× |

▲ |

▲ |

▲ |

|

Safety protection

|

| Electrostatic grounding |

▲ |

▲ |

▲ |

▲ |

| ionic wind remove static |

▲ |

▲ |

▲ |

▲ |

| when lose power |

○ |

○ |

○ |

○ |

| Emergency stop |

○ |

○ |

○ |

○ |

| Ex-proof |

▲ |

▲ |

▲ |

▲ |

| Original mode |

DCS-25 |

DCS-25FW |

DCS-25F |

DCS-25FL |

| Mark: “○”is standard function;“▲”is choose function ;“×”is not has function |

Main specialty

- Scope of application: Granular material or powder material of Packing bags(boxes and pails)

- Can be made into twin-type pakcer(except DCS-25(GO7N)和DCS-25(PO4G))

- Can made into semi-packing and palletizing line with conveyors, sewing machine, heat sealer, fall bag conveyor, reshaping conveyor, weight checker, reject conveyor, pallet magazine, stacker.

-

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!