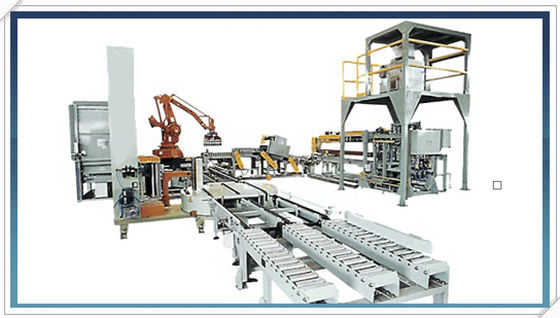

OPAL 25 Kg Valve Bag Automatic Packing And Palletizing Line For Non - Sticky Loose Powder

Broad Category:Valve Bag Automatic Packing and Palletizing Line

Name: VAPL Valve Bag Automatic Packing and Palletizing Line

A. What is 25 kg electronic packing scale:

Electronic packing scale consists of weighing unit, sewing machine, conveying device, pneumatic system, dust removal system, quantitative packing control, etc. the whole weighing process is controlled by PLC and completed automatically.

B. Working principle of 25 kg electronic packaging scale:

When the electronic packaging scale enters the automatic operation state, the weighing control system opens the feeding door to start feeding, which is a fast and slow feeding mode; when the material weight reaches the fast feeding setting value, stop the fast feeding and keep the slow feeding; when the material weight reaches the final setting value, close the feeding door to complete the dynamic weighing process;

At this time, the system checks whether the bag clamping device In the predetermined state, when the packaging bag has been clamped, the system sends a control signal to open the unloading door of the weighing bucket, and the material enters the packaging bag.

The bag clamping device will be released, and the packaging bag will fall automatically; after the packaging bag falls, the sewing bag will be carried out and transported to the next station. It operates automatically in such a cycle.

C. Generally, a packing & palletizing line includes: Electric Cabinet, sewing machine,Sewing conveyor, Bag push machine, Reshapen conveyor,Metal detector,Weight checker,Bag Rejecter,Ink-jet printer conveyer,Ink-jet printer ,Pallet magazine,Palletizing conveyor ,Robot, Wrapping Machine ,Finished palletizing conveyor.

D. According to the different styles of packaging bags, it can be divided into open mouth bag packing machine and valve type bag packing machine

1.Scope of application of our VAPL Valve Bag Automatic Packing and Palletizing Line:

1)Applicable material:

Non-sticky, loose powder.

2)Applicable filling containers:

The valve bag made of paper or other material with breathable micropores, such as film with breathable micropores.

2. Models and Technical parameters of our VAPL Valve Bag Automatic Packing and Palletizing Line:

|

Item

|

Short Name

|

Model Number

|

Max Capacity

(bags/h)

|

|

1)

|

Single packer type |

VAPL-120-25PV3 |

120 |

|

2)

|

Double packers type |

VAPL-200-25PV3X2 |

200 |

|

3)

|

Triple packers type |

VAPL-300-25PV3X3 |

300 |

3. Main Equipments composition of our VAPL Valve Bag Automatic Packing and Palletizing Line:

| Item |

Equipment |

Quantity

|

| 1) |

Automatic valve bag packer |

1 or 2 or 3 |

| 2) |

Automatic empty bag feeder |

1 |

| 3) |

Metal detector |

1 |

| 4) |

Weight checker |

1 |

| 5) |

Rejector |

1 |

| 6) |

Filled bag reshaping Conveyor |

1 |

| 7) |

conveyor |

Several |

| 8) |

Pallet magazine(include pallet feeder) |

1 |

| 9) |

Robot Palletizing |

1 |

| 10) |

Power cabinet and Control cabinet |

1 |

4.Functions and Characteristics of our VAPL Valve Bag Automatic Packing and Palletizing Line:

1)High degree of automation, Manually only need to put empty bags into the automatic empty bag feeder, empty pallets into the pallet magazine, all other processes are automatically completed by the equipments.

2)Perfect dedustinging system ensures that no dust escapes to pollute the environment during packaging.

Valve Bag Automatic Packing & Palletizing Line

| |

DCS-25PV1(3)-SI-AL

(signal scale for powder)

|

DCS-25PV1(3)-MU-AL

(multi-scales for powder)

|

DCS-25PV1(7)-MU-AL

(multi-scales for granule)

|

|

Scope of application

|

|

Suitable materials

|

Powder and thin granule

|

Powder and thin granule

|

Granule and powder material with good flowability

|

|

bag

|

Valve bag(automatic sealing bag)

|

Valve bag

|

Valve bag(automatic sealing bag)

|

|

Feeding type

|

Air flow

|

Air flow

|

gravity

|

|

Alternative feeding type

|

Screw, impeller

|

Screw, impeller

|

vibration

|

|

Technical parameters

|

|

Automatic supply bag machine

|

1 |

1 |

1 |

|

Number of packing scale

|

1 |

1 |

1 |

|

Feeding mouth

|

1 |

1 |

2 |

|

One swing bag can with maximum feeding mouth number

|

1 |

3 |

2 |

|

Weighing range (Kg)

|

10-50 |

10-50 |

10-50 |

|

Packing speed(bag/H)

|

100-300 |

150-250(signal line and signal packer)

300-450(signal line and two packers)

400-600(signal line and three packers)

|

200-600 |

|

Packing Accuracy

|

Generally (+/- )0.2%(Note: special materials shall depend on the industrial standard)

|

|

Automatic working progress

|

|

Automatic bag supplying

|

○ |

○ |

○ |

|

Automatic swing bag supplying

|

○ |

○ |

○ |

|

Automatic quantitative packing

|

○ |

○ |

○ |

|

Automatic bag sealing

|

○ |

○ |

○ |

|

Automatic falling bag

|

○ |

○ |

○ |

|

Automatic bag re-shaping

|

○ |

○ |

○ |

|

Automatic metal detector

|

○ |

○ |

○ |

|

Automatic weight checker

|

○ |

○ |

○ |

|

Automatic rejector

|

○ |

○ |

○ |

|

Automatic pallet supplying

|

○ |

○ |

○ |

|

Automatic stacking

|

○ |

○ |

○ |

|

Manual operation sequence

|

|

add empty bags into empty bag magazine

|

○ |

○ |

○ |

|

Move the bag which is rejected away.

|

○ |

○ |

○ |

|

Add pallets into pallet magazine

|

○ |

○ |

○ |

|

Move the full pallet away

|

○ |

○ |

○ |

|

Safety protection

|

|

Electrostatic grounding

|

○ |

○ |

○ |

|

ionic wind remove static

|

▲ |

▲ |

▲ |

|

Stop packing when lose power

|

○ |

○ |

○ |

|

Emergency stop

|

○ |

○ |

○ |

|

Ex-proof

|

▲ |

▲ |

▲ |

|

Mark: “○”is standard function;“▲”is choose function ;“×”is not has function

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!