25kg Semi Automatic Pouch Bag Beans Rice Grain Nuts Seeds Sugar Solid Granule Weigh Filling Packing Machin

A. What is the 25 kg packing machine ?

It is used to transport materials (normally powder or granule ) from the silo to the packaging container, and it also has the function of weighing,

B. Discription of 25 Kg packing machine ?

Electronic quantitative packaging scale is a combination of electronic scale and automatic control. It weighs when feeding until it is close to the preset packaging value. The computer quantitative packing scale is composed of several independent weighing units with the structure of feeding and discharging. The computer quantitative packing scale is suitable for the quantitative packing of 25kg-50kg, and the electronic quantitative packing scale is widely used.

C. Application of 25Kg packing machine:

Powder quantitative packaging machine is suitable for the quantitative packaging of powder, powder and powder materials in chemical, food, agricultural and sideline products industries, such as milk powder, starch, pesticide, veterinary medicine, premix, additive, condiment, feed, enzyme preparation, etc.; powder quantitative packaging machine is a combination of machine and instrument, controlled by single chip microcomputer, with automatic quantitative, automatic filling and automatic adjustment of measurement error Etc.

D. According to the different styles of packaging bags, it can be divided into open mouth bag packing machine and valve type bag packing machine

Main specialty :

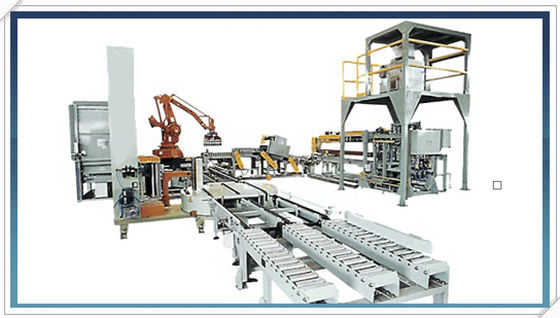

Valve Bag Automatic Packing & Palletizing Line for granule and powder material.

|

|

DCS-25V

|

|

Scope of application of our of our Packing Machine

|

|

Suitable materials

|

Granule and powder material with good flowability

|

|

Bag

|

Valve bag(automatic sealing bag)

|

|

Feeding type

|

Gravity

|

|

Alternative feeding type

|

Vibration

|

|

Technical parameters

|

|

Automatic supply bag machine

|

1

|

|

Number of packing scale

|

1

|

|

Feeding mouth

|

2

|

|

One swing bag can with maximum feeding mouth number

|

2

|

|

Weighing range(Kg)

|

25 |

|

Packing speed(bag/H)

|

200-600

|

|

Packing Accuracy

|

Generally (+/- )0.2%(Note: special materials shall depend on the industrial standard)

|

Advantages :

High accuracy

Easy clean out and maintence

After the machine installs you get hands on training and documentation

The air flow feed system is capable of high production rates while maintaining good accuracies.

Operator friendly easy set

Universal and industrial components give the machinery extra long life

PLC controller interface

The flexible and modular Packaging System

Main sub-suppliers:

| Name OF Outsourcing |

Sub-suppliers |

| Weighing Controller |

Uniplus F701 / Zhi Mei or Jie Man |

| Load Cell |

Mettler Toledo / Zhong Dian Hang Ce |

| PLC |

Mitsubishi |

| Touch panel ( option ) |

Mitsubishi |

|

Fold edge sewing machine

( option )

|

De chao |

| Pneumatic Equipment |

FESTO or SMC or airtac |

| Solenoid valve |

FESTO or SMC or airtac |

| Photoelectric switch |

Autonics |

|

Metal detector

( option )

|

METRON German |

| Robot ( option ) |

FUJI EC-102 |

| Motor |

Wan Nan |

| Sewing machine ( option ) |

De Chao |

| Electric cabinet |

Tong Ke |

| General Electric Component |

SCHNEIDER |

Utilities ( provided by buyer )

1. Power:

AC380V±10%;50Hz±2%(three phase and five wires);

2. Compressed Air:

Pressure: 0.55~0.7 Mpa;

Consumption: 0.3N m3/min;

3. Temperature: -10- +50(℃)

4. Relative humidity: ≤90% (no coagulation water)

5. De-dusting

Negative pressure:6-8 pa

Blowing rate: 1800m³/H

Advantage : Fast packing speed , high precision, less dust

our advantage products :

valve bag automatic packing line,

ton bag weighing bagging machine,

bag ( bag package into box ) packaging and stacking production line ,

our hot sales products :

1. 25kg open mouth bag packing & palletizing line,

2. 25kg valve type bag packing & palletizing line,

3. Ton bag packing machine

4. liquid filling machine (10L-50L;/ 50L-250L; / 1500L)

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!